Hotend development

7. Januar 2012

Today hotend.. !

no boring stuff… the hotend is really important for the 3dprinter.

The hotend is the mainpart why a 3d-printer with plastic works so well.

First we started 3d-printing or repraping we bought some hotends in different shops, to check out how they work.

Printing PLA was the most of the time no problem. First prints with ABS where horrible.

Firstlayers wasnt really strong. Most of the time we dont get the right temperature.

So we print about a week direct in the trash-can.

At our visit at a big electricparts-shop in our city we found a infrared temperaturemeasure gun about 20-30Eur.

Temperature area -30 to 260°c. Maybe not so accurate, but for measure the hotendend and estimating how hot it is… its enough!

Back at home… spending the hole evening meassuring of all hotends we have. Surprised we see that the most of the hotends dont have the temperature at the outcase that was displayed in the Print-interface.

So we were missing about 20°c to print ABS. >230°c was the temperature we wanted to have. So we set the temperature higher until we see that the ABS-filament comes with good speed out of the nozzle. I think the perfect printtemperature for ABS is right before it gets really liquid. At starting my printer and setting it to temperature, i extrude a small ball of filament and squeeze it between my fingers.

It should be really soft for few seconds and easy to knead. (be careful with that maybe use a thing to test it… and dont burn your fingers… for me its no problem to touch hot things for a few seconds)

For a few days it works pretty well and we tried to print full ABS-sets. After printing 55% of a set the nozzle gets blocked and we throw another set in the trash-can.

Okay no more stupid stuff lets develop our own hotend to learn how it gets better!

In my regular job i am a metal cutting mechanic and so drilling milling and turning of miscellaneous materials is no problem.

For the most parts we decide to use brass, especially for the nozzle.

Brass is a wear resistant material. It melds about 900-950°c.

(standart aluminum melds about 600-700°c)

Okay brass ready.. somewhere in the garage..

Next we need something to isolate the hotend from the extruder. Furthermore its important to hold the filament really cool before it comes in the heatzone of the hotend.

This allows to give full pressure on the filament while printing. We tested teflon (polytetrafluretylen-PTFE) as isolator. Temperature area about -20°c to 260°c. For short times up to 300°c

PTFE has high sliding performance. Perfect for the infillarea of the hotend.

Some tests … only waste… doestn work!

Bursted hotends! Melting hotends. Ah i forget.. some table-sets for the trashcan.

Looking in some books from my regular work makes it clear. PTFE has a tensile strengh of 10 N/mm².

So we decide to start some research and find a better material.

Okay looking in the area of high temperature isolators makes my moneybag really sad. We dont want to build a jet turbine…

Hotend.. 3dprinting.. back to topic…

We found a good material as alternative:

Peek (polyetheretherketon) has a Temperature area about -65 to 260°c.

Peek (polyetheretherketon) has a Temperature area about -65 to 260°c.

For short times up to 300°c.

Its resistend against chemicals and the most important:….. tensile strengh of 97 N/mm²

Nine times stronger then the PTFE. Also it got good sliding performance.

With about 35-50Eur for a short piece (D10x500) we were ready to start building our first prototyp:

I will save all the experiments and the fotos of them and will show you some finished work!

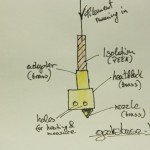

Some months ago our mainidea was this:

We want to build a hotend which works with PLA and ABS. It must be possible to change the nozzle in a few minutes. Heatthermistor and Heatsensor must be replaceable too. Replacing and dismounting should be easy.

The isolation should be so good, that the filament only melds in the area where the nozzle is. (avoid ouze)

The hotend will be designed for a max. working temperature of 260-280°c, to have some air to the top. To use the new hotend on all of our extruders, we decide to make the isolation with a out-diameter of 10mm. So it should fit on the most extruders.

Lets come to the parts:

Peek – Isolator(adapter to the extruder)

We designed the isolator so that it fits over a thread to the adapter. We make a cut-in to clamp the hole hotend and hold it in position.

For 3mm filament we designed the bore thru this part with a dia of 3.5mm.

Next part Adapter:

The Adapter is made of Brass. Inside a M10-thread on the outside hexagon for a wrench. So it should be easy to screw them together. The M8-Outside-Thread is for screwing the isolator+adapter into the heatblog. Threads demonstrat no really fullcontact between the parts. So the temperature wont spread so much.

Thats important for the brass but it will save the peek too.

The Heatblock is made of Brass. Inside M8-thread to screw in nozzle + adapter. On the side we drill two holes for thermistor and the heat-resistor. So you have access to them the hole time, if anything needs to be replaced.

The Heatblock is a bit bigger. So it could buffer and compensate some temperature

Last part but the most important… the nozzle:

Made of brass.. i think you guess so! One side have got the M8-outside-thread on the other side its turned to a pointed surface. Inside we made a 3mm bore. We drill the 3mm bore so deep that only 1mm material left.

So the material will compressed in this area and only have to get thru the 0.35mm big and 1mm long nozzle. After a lot changes we decide that that works the best!

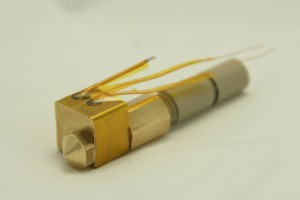

Now the assembled hotend: on the right ready to use with thermistor and resistor

![]()

We tried to drill different nozzles.With 0.5 – 0.35 – 0.25 we got great results in PLA and ABS.

The isolation works nearly perfect. In some cases we try to isolate the hole hotend with a surrounding of capton and mineral wool.

Lets come to some results of printing:

All printed with 0.35 nozzle ABS black, white or green:

Be warned in the next days i will update this post and will ad some drawings and more information about our new Hotend.

We called it: geeksbase – hotend v 1.0

Feel free to leave some comments.. !

12. Juni 2012 um 05:55

Hi, You design looks great and i would like to try it out myself.

Do you have some mechanical drawings of your design?

Please mail them to me if you have.

Thanks and keep up the good work.

30. Juli 2012 um 20:03

Just desire to say your article is as amazing. The clarity in your post is simply nice and i could assume you’re an expert on this subject. Well with your permission let me to grab your feed to keep up to date with forthcoming post. Thanks a million and please keep up the rewarding work.

25. August 2012 um 18:12

Hi guys,congratulations! Very impressive pjocert!!! We are working in a fab lab in sevilla, spain Hopefully joining the bigger network soon Was wondering about the distribution license o Ultimaker. You mention it is open source, but i cannot find after quite some search the actual license Construction and electronics plans, etc.Of course, we will try to get one of your machines as soon as we get some cash The early makerbot that we have had for some time is being hard for us, even if we love it. It will be nice to have the two machines and play with both of them, compare It would also be very nice if you could publish your presentation about innovation ecologies in the Botacon [?] event that you were mentioning in another post!All the very best _ osfa**

4. September 2012 um 00:43

I believe that is among the most vital information for me. And i’m glad studying your article. But wanna remark on some basic issues, The web site taste is wonderful, the articles is actually excellent : D. Excellent process, cheers

16. September 2012 um 03:11

Thanks for some other wonderful post. Where else may anybody get that kind

of information in such an ideal means of writing?

I have a presentation subsequent week, and I’m at the search for such information.

26. September 2012 um 13:38

Hey!

Iam glad that you like our projects. We try to make new things, or make some things better.

With mak**bot* i got some problems too. So we decide to build our own stuff.

looking forward to hear from you!

Kindest regards

Ben

4. Oktober 2012 um 16:23

Hey There. I found your blog using msn. This is a really

well written article. I will be sure to bookmark

it and return to read more of your useful information.

Thanks for the post. I’ll definitely comeback.

22. März 2013 um 21:01

Very interesting info !Perfect just what I was searching for!

26. März 2013 um 12:46

I think this is one of the most vital info for me. And i’m glad reading your article. But should remark on some general things, The website style is great, the articles is really great : D. Good job, cheers

3. April 2013 um 17:49

Whаt’s up, just wanted to say, I loved this blog post. It was funny. Keep on posting!

12. April 2013 um 12:36

Simply desiгe tο sаy your artіcle is aѕ аstοunding.

Тhe clarity on your put uр is

just great anԁ that i can assume you’re an expert on this subject. Fine along with your permission allow me to seize your RSS feed to stay up to date with coming near near post. Thank you 1,000,000 and please continue the rewarding work.

13. April 2013 um 16:37

Hey there, You have done a great job. I’ll certainly digg it and personally recommend to my friends. I am sure they’ll be

benefited from this site.